Focus on

Higher stability/flexible production

High reliability and good environmental performance

The five axis machining center suitable for machining complex special-shaped parts can realize the machining of complex parts that are difficult or basically impossible to be machined by ordinary machining centers, so it is widely used in aerospace, shipbuilding, mold and other processing industries. High machining accuracy One time clamping can complete the machining of multi axis processes such as turning and milling, so the precision of five axis vertical machining center is higher than that of ordinary machining center.

The processing is stable and reliable to realize computer control, eliminate human error, and the processing consistency of parts is good, and the quality is stable and reliable.

When the high flexible processing object changes, it is generally necessary to change the numerical control sequence, which shows good adaptability and saves preparation time for production. Based on the five axis machining center, an automatic manufacturing system with higher flexibility can be formed.

The five axis machining center with high productivity has high machining accuracy and high rigidity of the machine tool bed. It will automatically select favorable processing amount. The productivity of the five axis machining center is high, generally 3 to 5 times that of the ordinary machining center. It can handle the processing of some complex parts, and its production efficiency can be improved by more than ten times or even dozens of times.

Higher stability/flexible production

High reliability and good environmental performance

The five axis machining center suitable for machining complex special-shaped parts can realize the machining of complex parts that are difficult or basically impossible to be machined by ordinary machining centers, so it is widely used in aerospace, shipbuilding, mold and other processing industries. High machining accuracy One time clamping can complete the machining of multi axis processes such as turning and milling, so the precision of five axis vertical machining center is higher than that of ordinary machining center.

The processing is stable and reliable to realize computer control, eliminate human error, and the processing consistency of parts is good, and the quality is stable and reliable.

When the high flexible processing object changes, it is generally necessary to change the numerical control sequence, which shows good adaptability and saves preparation time for production. Based on the five axis machining center, an automatic manufacturing system with higher flexibility can be formed.

The five axis machining center with high productivity has high machining accuracy and high rigidity of the machine tool bed. It will automatically select favorable processing amount. The productivity of the five axis machining center is high, generally 3 to 5 times that of the ordinary machining center. It can handle the processing of some complex parts, and its production efficiency can be improved by more than ten times or even dozens of times.

Stable/efficient/goodenvironmentalperformanceShort

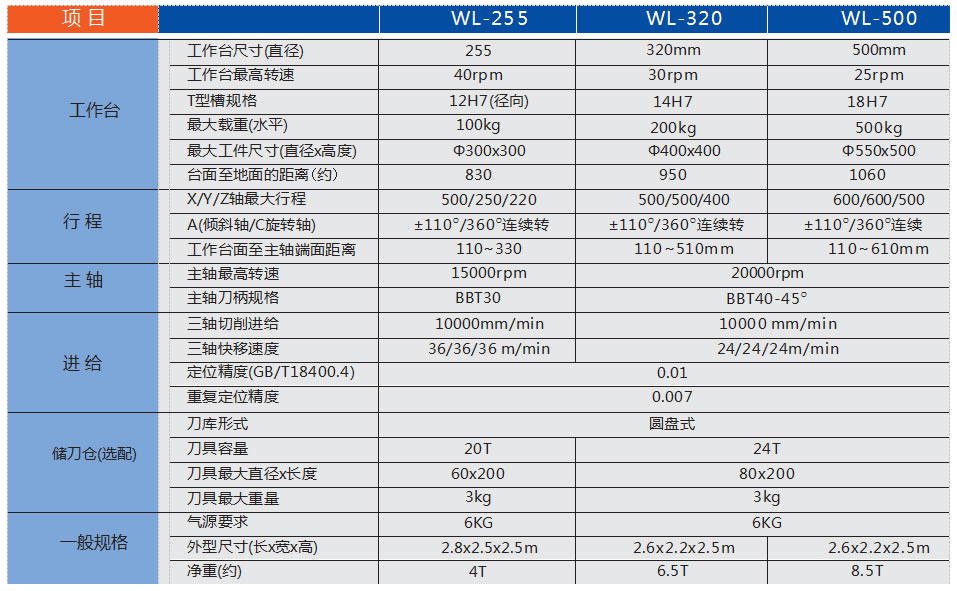

Product Details

Product Details

Largerprocessingarea/higherperformance/higherrelia

Product Details

SMARTMACHINE●Seamlessswitchingbetweenturningandmil

Product Details

Welcome to call the good speed, fast and good, it is good speed!